Establishment of the company engaged in the wholesale of packaging materials called Stirolplast.

Establishment of PolyER manufacturing company in Pereslavl-Zalessky, at Slavich site. Implementation of polystyrene sheet and packaging processing.

Acquisition and renovation of 10,000 square meters of production area of building No. 31.

Expansion of extrusion and thermoforming facility.

Implementation of polypropylene processing using Gabler M93, Varius and Kiefel machinery purchased in Germany.

Entrance to the market of polypropylene packaging.

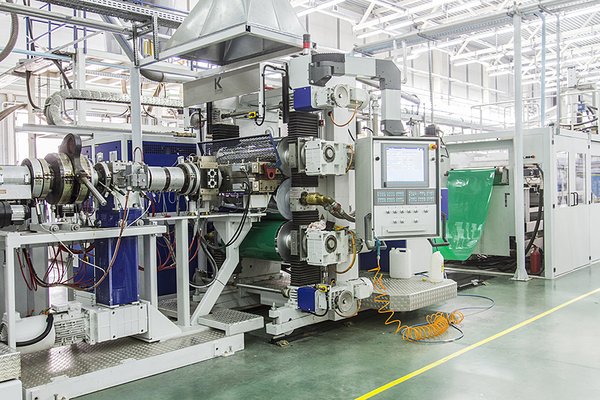

Launch of new German-made Kuhne extrusion line. Over 100 mln. PS and PP products were produced at 20 thermoforming lines.

Commissioning of new thermoforming equipment. Product range expansion and increase of PP packaging market share.

Launch of German-made Battenfeld extrusion line. Quality Management System has been certified according to ISO 9001:2008.

Production of polystyrene and polypropylene sheet for FFS lines in compliance with the requirements of international companies.

Construction of new manufacturing facility with the floor area of 3 600 square meters.

Launch of PET processing at LUIGI BANDERA extrusion line and Kiefel thermoforming line. Production of PET sheet and a line of universal PET containers.

Launch of in-line production of polypropylene packaging.

Expansion of manufacturing facilities up to 20,000 square meters.

Start of export supplies to EU and CU states.

Start of PET packaging production for automatic lines tailored to the individual requirements of the customer.

Expansion of PET packaging range.

Twofold increase of PP container manufacturing capacities.

Start of PP packaging manufacture for meat market segment, including MAP.

Employees insurance under the Voluntary Medical Insurance Program.

Launch of A class warehouse facility with the total floor area of 5,500 square meters.

Launch of Italian AMUT in-line equipped with automatic prepacking starting from 10 pcs.

PolyER joined SEDEX international system of socially responsible companies.

Acquisition of the line for automatic pasting-in of napkins using ultrasound method.

Launch of the second Luigi Bandera PET extrusion line, expansion of PET packaging range.

Introduction of FSSC 22000 the international food safety management system (Food Safety System Certification).

PolyER becomes the member of Yaroslavl Regional Chamber of Commerce and Industry.

Expansion of GABLER VARIUS-type thermoforming machinery facility up to 5 pcs.

Acquisition of 8,000 square meters of industrial and warehouse areas.

Launch of the third LUIGI BANDERA PET extrusion line.

Increase in PP and PET thermoforming capacities.

Expansion of PET and PP packaging range.